The Laitram Machinery Intraflow Briner, a unique and integral link in the CoolSteam Black Pasteurization and Dry Roasting System, radically changes how the nut industry creates salted and seasoned products.

Laitram Machinery’s Intraflow Briner is a unique brine application system for tree nuts that radically differs from traditional drum brine systems. The Intraflow Briner links Laitram’s fully integrated pasteurization and roasting system. An option on the CoolSteam Black System, Intraflow creates a continuous flow of product between CoolSteam Pasteurizer and Precision Roaster, eliminating the necessity for additional material handling through conveyance, transfer points, or oscillating conveyors as is needed with traditional drum brine applicator systems. The Intraflow Briner can be implemented as a first step to the Laitram Precision Dry Roaster for processors interested in only dry roasting products.

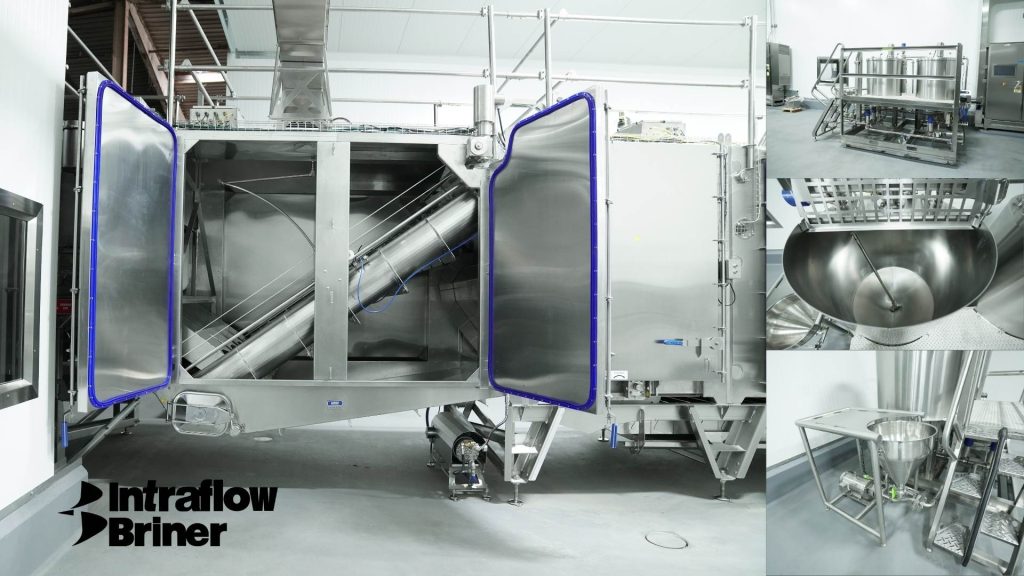

- Intraflow consists of four 316 stainless steel augers with accompanying troughs across the width of the downstream dry roaster belt. Transport all nut types while applying salt brine or seasoning to seamlessly create salted or seasoned products.

- Intraflow can be used as pass-through conveyance for non-salted products during pasteurization and roasting.

- Intraflow utilizes a counter-flow process to consistently apply salt brine in each trough for even, full coverage on each nut.

- Tree nuts never sit stagnant in Intraflow. The product’s constant movement through the system ensures consistent and even coverage. The nuts are de-watered and transported directly to the roaster.

- The system includes a brine skid consisting of mixing and holding tanks to create customized brining solutions for any product recipe.

- All controls, including auger speed and salt brine flow rate, are integrated into one easy-to-operate control panel. Real-time feedback and data are captured in one-second intervals.

- Cleaning and sanitizing the augers is easy with an automated CIP cycle that utilizes high-pressure nozzles to clean the Intraflow Briner.

The Intraflow Briner is an integral link in the CoolSteam Black System. It represents a paradigm shift in tree nut processing, delivering a comprehensive solution that elevates efficiency, quality, and food safety.

Watch Laitram’s CoolSteam Black Installation at JSS Almonds here.